AQL Table Acceptance Quality Limit for Product Inspections

The AQL table is widely used to assess quality of the batch without checking the full quantity of products. It is the main tool of the inspectors to use during product inspection, as well as the main metric for importers to decide whether to accept a certain batch of products.

AQL stands for an acceptance quality limit that:

1. Indicates the number of samples that should be selected from the total quantity of your order during inspection.

2. Determines the maximum number of defects allowed in a batch of goods.

It can be considered as the maximum limit of defects for a certain number of products in the order.

How do I determine the right sample size and acceptance number by using an AQL table?

As an example, in an inspection of a 3,500-unit lot, with an Acceptable Quality Level of II, Table A indicates that sample size code letter should be "L". Table B indicates that the sampling size of "L" should be 200 units. For an AQL of 2.5, the corresponding acceptance number is 10.

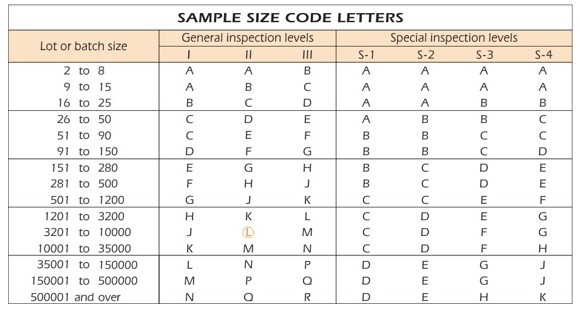

AQL Table A: Sample Size Code

In the first part of the AQL table, there are General and Special inspections levels. The primary sample size that you will use for inspection is the general inspection level, while testing of a specific product is reserved for special inspection level.

AQL Table A to determine a sample size

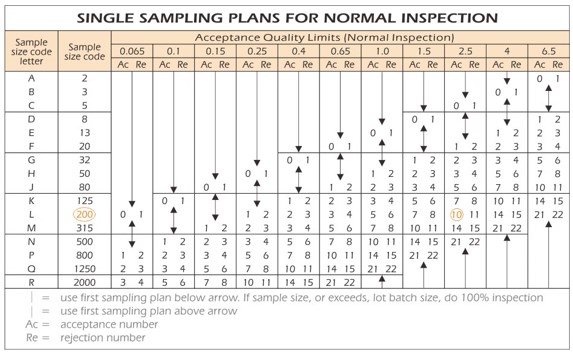

AQL Table B: Sampling Plan

In the second part of the AQL table, there are acceptance quality levels, and the sample size code letters are mentioned. Here you can see that your sample size code letter is corresponding to a sample size of X units.

AQL Table B to determine acceptance quality limits